6.1 Definition of an Adhesive

It is important to first clarify and understand the following key terminology and concepts. Doing so will help in understanding different adhesive types and their properties.

Adhesive: An adhesive is any substance that, when applied to the surfaces of the materials (substrate), bonds the surfaces together and resists separation. Adjectives may be used in conjunction with the word ‘adhesive’ to describe properties based on the substance’s physical or chemical form, i.e. ‘flexible’ adhesive or ‘hybrid’ adhesive.

According to DIN EN 923, an adhesive is defined as a non-metallic binder that acts via adhesion and cohesion. ASTM D907-06 defines an adhesive as ‘a substance capable of holding materials together by surface attachment’.

6.1.1 Adhesive Terminology

Open time: The maximum allowable time between when the adhesive has been mixed (2Cs), activated or applied (hotmelt) and when the parts can be assembled without compromising the ultimate strength.

Nozzle life or dispense time: The maximum allowable time between the subsequent dispenses of 2C adhesive from the same nozzle or static mixer without causing clogging due to cured or partially-cured adhesive being present.

Static mixer: A precision-engineered dispensing device without internal moving components used for the continuous mixing of 2C adhesives. As the streams move through a static mixer, the series of baffles continuously blend the materials, as can be seen in Figures 147 and 148.

Static mixers, or ‘static mix nozzles’, are engineered devices that are designed to mix the 2C adhesives correctly; as such, they should not be altered in any way without first validating the performance of the mixed and cured adhesive.

Working Time: The maximum allowable time between applying the adhesive to a surface and mating the surfaces without compromising the ultimate bond strength.

On-part life: Like working time, on-part life is the time before a solvent or water-borne adhesive is applied to a substrate and will no longer wet out on the surface once the mating substrate is applied. For surface treatments or activators it also defines the time over which a material will remain active on a surface or component and be usable without the need for reapplication.

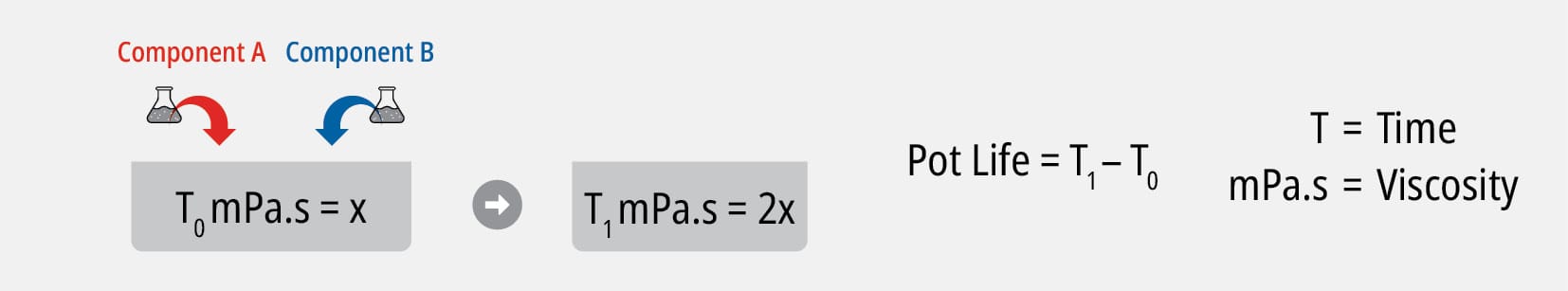

Pot life: The time it takes for the viscosity of a mixed 2C adhesive system to double. For example, if we have a mixed resin system with an initial viscosity of 10,000 mPa.s and the viscosity increases to 20,000 mPa.s in 30 minutes, then the pot life of the resin system is 30 minutes. Pot life only indicates how fast or slow the adhesive system cures; it does not necessarily define the amount of time the operator has to work with the adhesive in their application.

Skin over time: Skin over time is the time it takes for the surface of the adhesive to form a skin after exposure to atmospheric pressure at 25 ± 2°C, 50 ± 5% RH.

Fixture time: The time at which an adhesive bond develops handling strength (see the definition below). The standard test method for determining the fixture time is as follows:

- Lap shear standard 25.4 mm x 101.6 mm (1 in x 4 in) substrate joint is assembled using adhesive, overlap of 12.7 mm (0.5 in) with no induced gap

- 3 kg (6.61 lb) mass applied to assembly

- Time is measured to the point where a 0.1 N/mm2 (14.5 psi) is held for 10 seconds

Full cure time: The time required for the adhesive to achieve the final desired properties. Full cure time may change with the cure temperature.

Handling strength: A (relatively) low level of overall bond strength that allows substrates to be handled, moved or unclamped without disrupting the curing process or affecting the ultimate bond strength. Note that handling strength is assembly-specific.

Bonding offers limitless strength

See for yourself in our free LOCTITE® XPLORE e-learning.

Log in and select the chapter Introduction to Bonding to learn more.