5.4.2.3 Robotic Dispensing

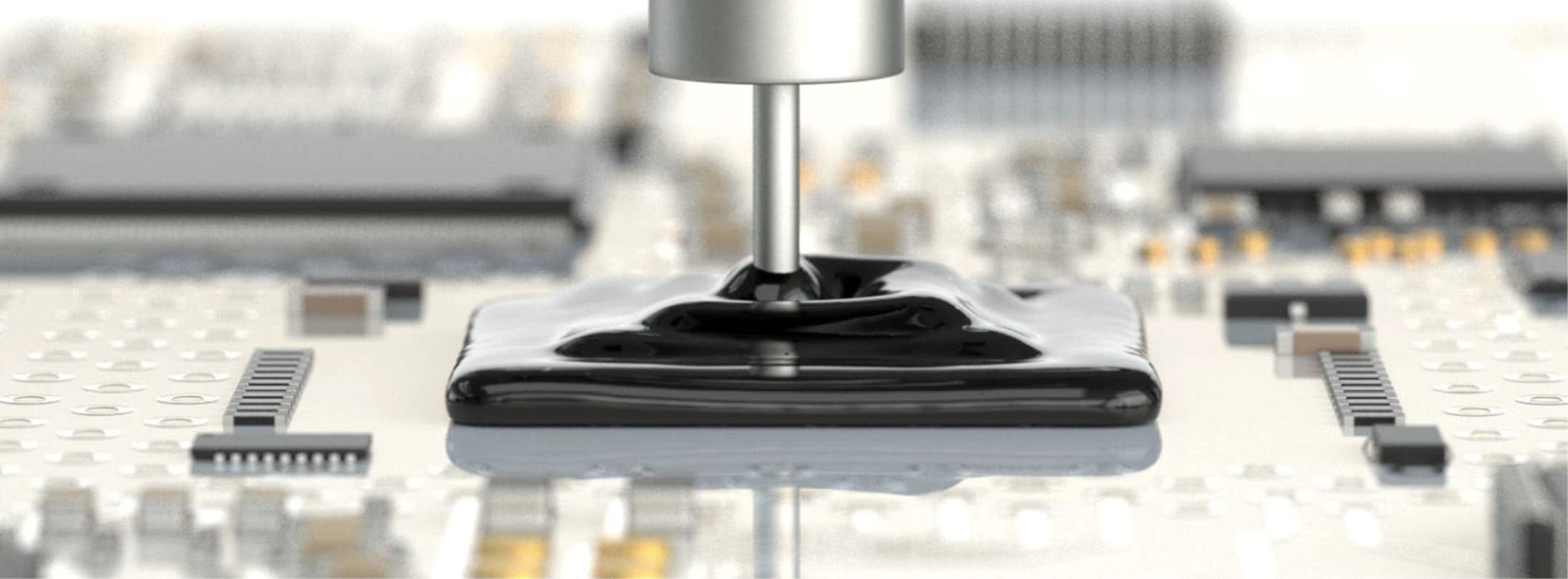

Fully automated dispensing is the ideal situation for any high-volume bonding application. With this application, nearly every aspect of the dispensing of adhesive is controlled by an automated process, which may include multi-axis robots. Adhesive volume, mixing, flow, bead size and bead location are all pre-programmed and thus have the highest accuracy and repeatability.

Nearly any adhesive can be integrated into a fully automated dispense system; however, the volume of parts produced must justify the cost of installing a fully automated line. While the overall cost per part will decrease, along with the total volume of adhesive used, there is a large upfront capital expenditure that must be accounted for.

With automated dispensing, part quality is the highest and cost is the lowest.

5.4.3 Fluid Characteristics of Adhesives

Several additional characteristics should be considered when specifying an adhesive for an application. As with any unique fluid or paste, there will be several properties unique to the particular chemistry that will affect how and where it can be used.

Regardless of the chemistry, all adhesives exhibit one or more of these properties:

- Thixotropy

- Viscosity ranging from ‘water thin’ to paste (i.e. 1 mPa.s to greater than 200,000 mPa.s)

- Adhesive texture, i.e. ‘stringy’

- Viscosity/temperature relationship sensitivity

- For 2C adhesives: Viscosity changes over time after mixing