5.4.2.2 Semi-Automatic Dispensing

Semi-automatic dispensing is an adhesive dosification method that incorporates the added benefit of dispense technology but also contains a human component. The volume, flow or bead size may be controlled automatically by the equipment, with the human factor controlling the placement of the adhesive on the part.

Continuing with the previous manual dispensing example, if a lower viscosity adhesive cannot be selected for the application (perhaps due to a vertical or overhead orientation), a pneumatic-powered dispense gun may be employed to prevent operator fatigue.

While semi-automatic systems do not fully control for all the factors that may impact assembly quality, they do help to control for repeatability, consistency, accuracy and adhesive cost by controlling the amount dispensed.

As a general rule, semi-automated dispense processes improve quality assembly and reduce costs and operator turnover.

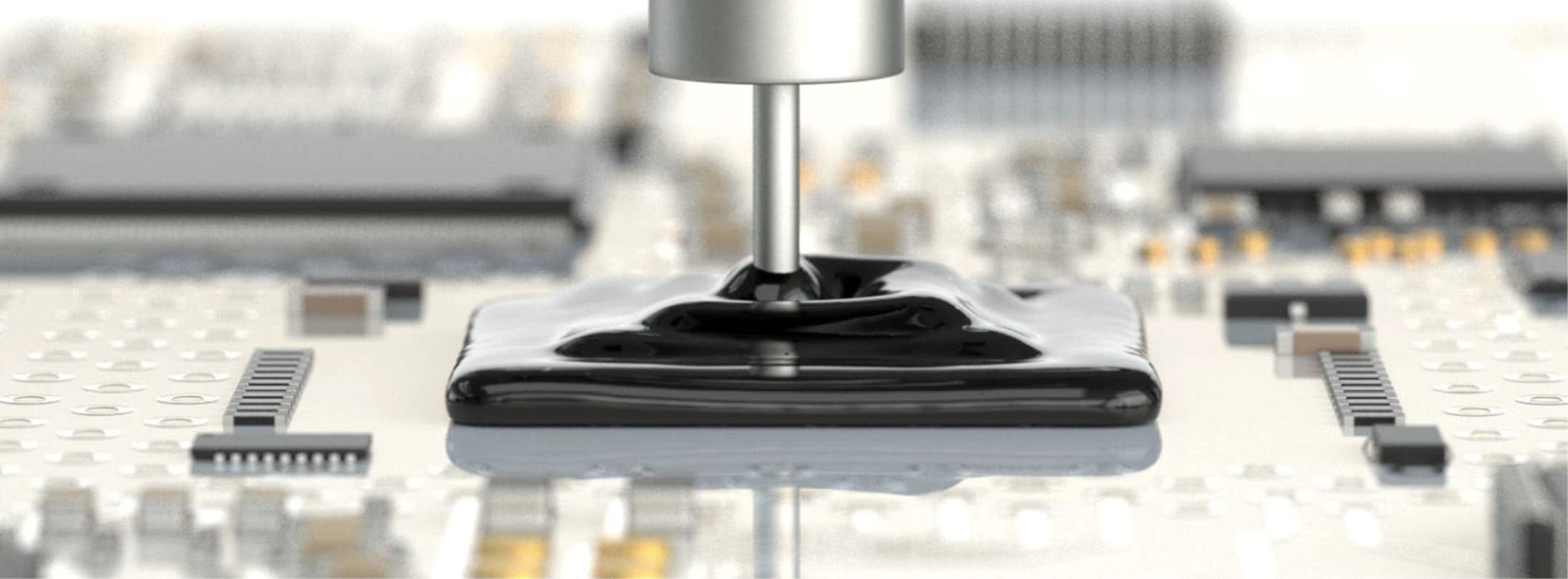

5.4.2.3 Robotic Dispensing

Fully automated dispensing is the ideal situation for any high-volume bonding application. With this application, nearly every aspect of the dispensing of adhesive is controlled by an automated process, which may include multi-axis robots. Adhesive volume, mixing, flow, bead size and bead location are all pre-programmed and thus have the highest accuracy and repeatability.

Nearly any adhesive can be integrated into a fully automated dispense system; however, the volume of parts produced must justify the cost of installing a fully automated line. While the overall cost per part will decrease, along with the total volume of adhesive used, there is a large upfront capital expenditure that must be accounted for.

With automated dispensing, part quality is the highest and cost is the lowest.