5.3.2 Calculating Adhesive Bead Size

Once the bond line dimensions have been calculated and the overall volume of adhesive has been determined, the next step involves factoring in the squeeze-out and calculating the appropriate bead size for dispensing. At this point, a predefined length of bond geometry based on the part design will have been established. Using the volume, bond length and radially defined bead geometry, calculating the required bead diameter is quite straightforward.

For example, here are calculations for bonding the shell of a dry freight shipping container:

| 20 metal components | Production |

|

|

| Recommend the (1) bead diameter needed to properly fill the gap and utilise all of the available surface area. Then, calculate adhesive usage (2) per container, (3) per year, (4) per day and (5) cost. |

1 Find the volume of adhesive per beam assembly.

163.50 cm * 2.54 cm * 0.10 cm = 41.53 cm3

2 Add squeeze-out factor of 20%

41.53 cm3 * (1.00 + 0.20) = 49.83 cm3 = 49.83ml

Now that we have a calculated volume per assembly, we can calculate the suggested bead diameter.

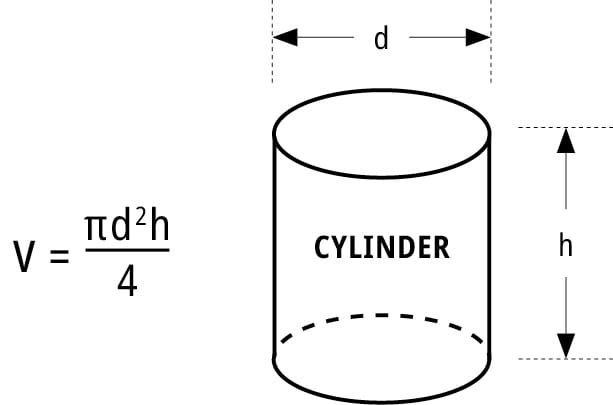

Volume of a cylinder (adhesive bead, as dispensed)

As this is an estimate, we can round our bead diameter to a commonly relatable diameter in industry 0.635 cm (¼ in) to err on the side of caution (especially if manual dispensing is involved).

The above calculation will provide you with the diameter of the aperture required for dispensing based on the volume of adhesive required to fill the calculated bond line. For specific on-part measurements, a different calculation must be used as the adhesive will not retain a perfectly cylindrical shape once dispensed.

Let’s recall the original calculation of 49.83 ml per beam. As 20 beams are needed for one dry freight shipping container:

(2) Volume adhesive * total components = total adhesive container

49.83 ml/beam * 20 beams/container = 996.6 ml/container

996.6 ml per Container/300 ml Cartridge = 3.32 cartridges/containers

There are 4,000 containers produced per year.

(3) Total Containers * Adhesive per container = total adhesive/year

4,000 * 996.6 ml = 3,986,400 ml/year

There are 13-14 containers produced per day.

(4) 996.6 ml/container * 13.5 containers/day = average 13,454 ml or 45 pieces, 300 ml tubes/day

Adhesive cost is $20 per 300 ml cartridge.

(5) 3,986,400 ml/year * ($20/300 ml) = $265,760 per year

45 pieces 300 ml tubes/day * ($20/300 ml) = average $900 per day

3.3 cartridges/container * $20/cartridge = $66 per container

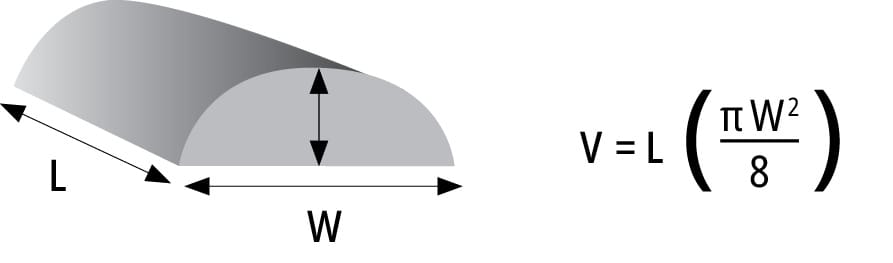

For an on-part calculation of the volume dispensed, see the following equation:

This calculation is particularly valuable when performing spot checks on adhesive volume dispensed to ensure a high degree of consistency and quality.