5.2.1.7 Surface Energy

The surface energy of the substrates should be a primary consideration when choosing a bonded assembly. For a comprehensive review of surface energy and polarity, see Section 4.

5.2.1.8 Surface Roughness

Surface roughness is another property that can affect not only the ability of an adhesive to wet to a surface but also the adhesion properties of the assembly. One example of manipulating a surface’s roughness for better adhesion is the recommended preparation procedure. It is recommended (when possible) that shot blasting be used not only to knock any loose material away from the surface before performing the repair but also to effectively increase the surface area the floor repair products will have to bond to, thereby increasing the adhesion.

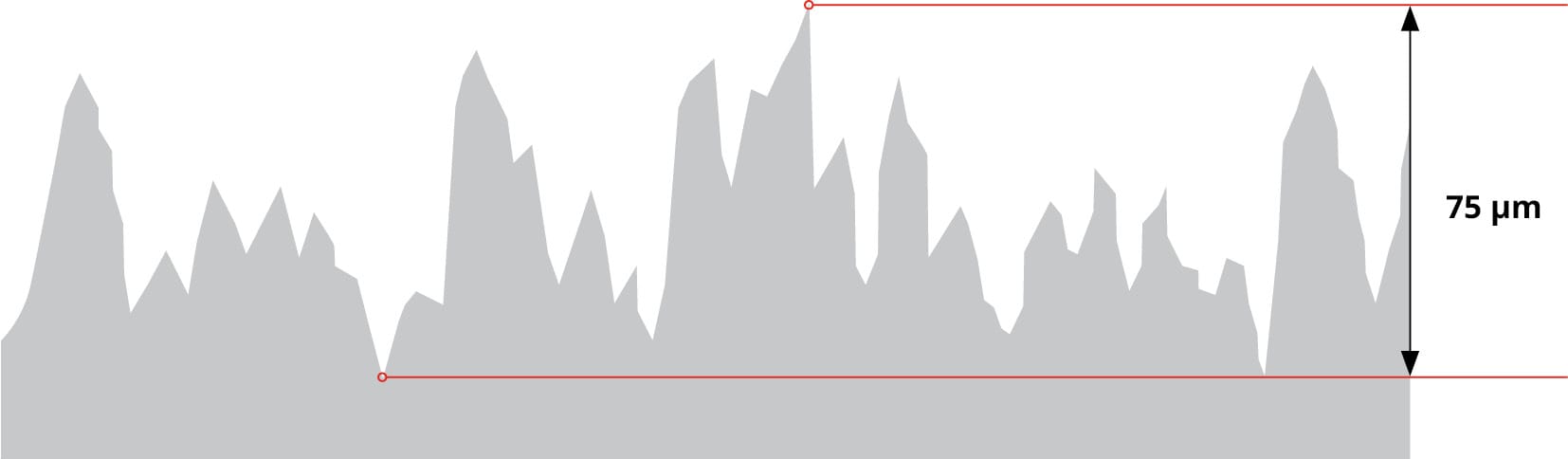

The same principle can be used for many chemistries, which is why an adhesive product’s TDS will include shear adhesion results for metal substrates that have been grit blasted. Typically, the roughness of a surface is measured in a unit of length, which represents the average height between the peaks and valleys on the roughened surface (Ra). In general, surface roughness is determined by the manufacturing processes used to produce materials as well as preparation steps such as sanding or grit blasting. Therefore, this profile will vary. Figure 134 shows a 75-micron surface roughness profile typical of a grit-blasting preparation step. Note that there is no general rule of thumb for surface roughness when preparing a surface for bonding since the interaction between the roughness and the adhesive will also be affected by the surface tension or by the ability of the adhesive to flow into the microscopic peaks and valleys to form a good bond.