5.2 General Design Guidelines

The following guidelines should be used as overarching principles when designing a bond line within an assembly:

1. Maximise Shear/Minimise Peel and Cleavage

Note that from the stress distribution curve for cleavage and peel, these bonds do not resist stress very well. The stress is located at one end of the bond line. Whereas, in the case of shear, both ends of the bond resist the stress.

2. Maximise Compression/Minimise Tensile

Note that from the stress distribution curve for compression and tension, that stress was uniformly distributed across the bond. In most adhesive films, compressive strength is greater than the tensile strength. An adhesive joint that is feeling a compressive force is less likely to fail than a joint undergoing tension.

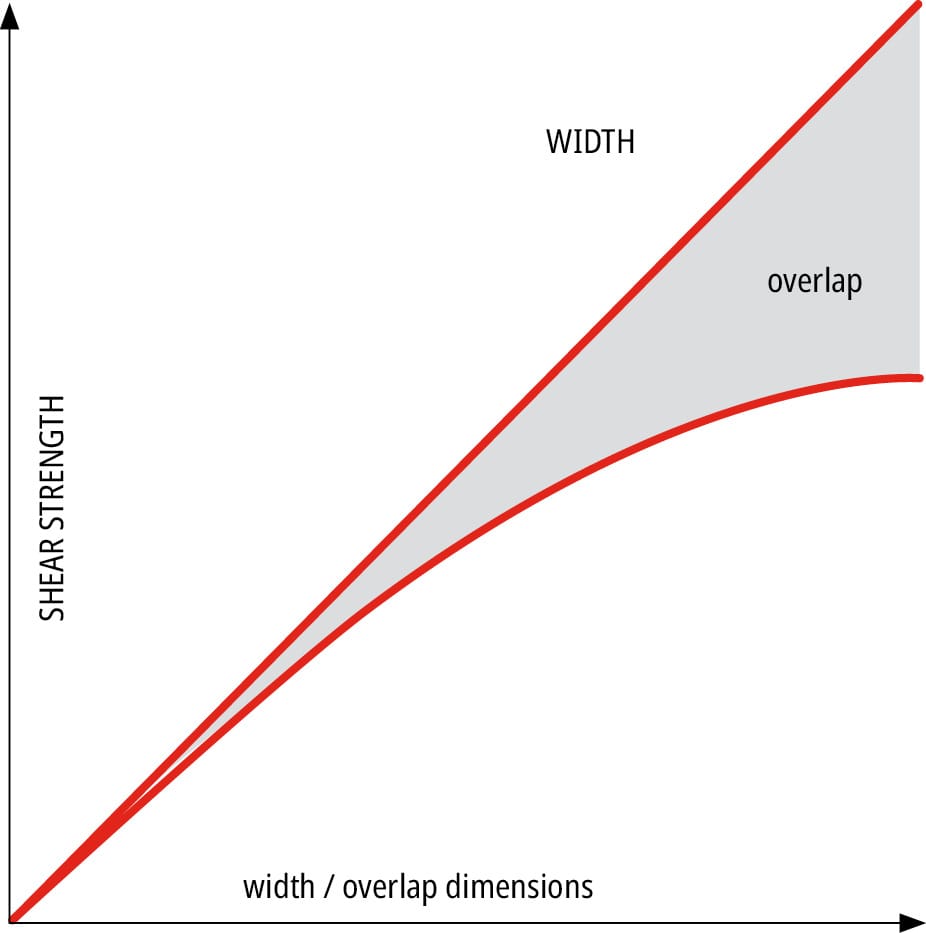

3. Joint Width Is More Important than Overlap

Note that from the shear stress distribution curve (see Section 4), that the ends of the bond resist a greater amount of stress than does the middle of the bond. If the width of the bond is increased, the bond area at each end also increases; the overall result is a stronger joint. In this same overlap joint, if the overlapping length is greatly increased, there is little, if any, change in the bond strength. The contribution of the ends is not increased. The geometry of the ends has not changed; thus, their contribution to the bond strength has not changed.