5.1.5 Cylindrical Substrates

The bonding of cylindrical elements (rods) with a head-to-head or butt joint should be avoided due to the critical sensitivity to bending moments (peel/buckling). Much like planar substrates, cylindrical assemblies joined with this method are particularly weak.

This shortcoming may be overcome by utilising different geometries characterised by greater bending strength and greater extension of the bonded surface. As can be seen in Figure 118, a strong and effective joint requires engineering with geometries that allow stresses to be evenly distributed over the bond area. These examples are representative only and are not a comprehensive list.

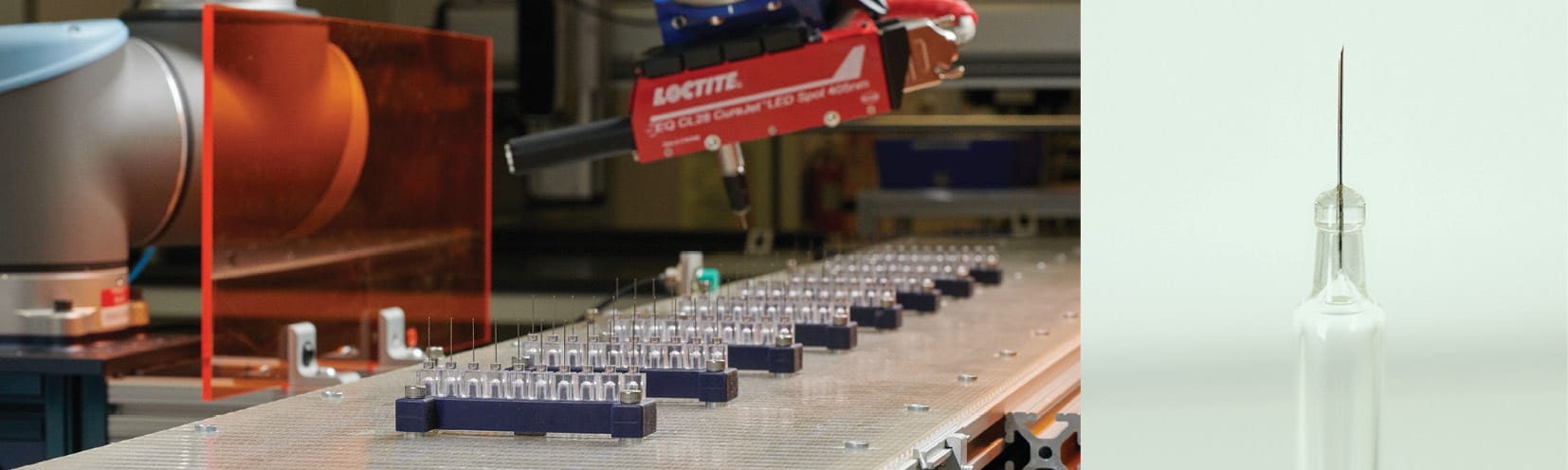

An example of this joint in Figure 119 includes the bonding of needles in medical devices.

| LOW RESISTANCE | POSSIBLE DESIGN SOLUTIONS |