4.4.1 Shear Stress

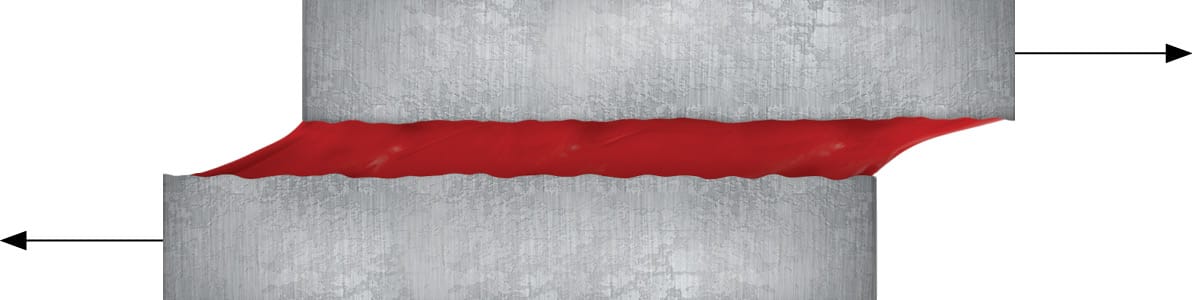

Shear stress results from the force applied parallel to the joined surfaces. Adhesive shear strength is an adhesive bond’s resistance to this stress and is reported in the load per area of the bonded overlap.

The shear strength reported on an adhesive’s TDS is the product of testing on standardised specimens. These data points are a good screening tool for selecting adhesives to test on actual or prototype assemblies, which will have a different geometry and stress distribution than the standardised tests and are necessary to accurately predict the joint’s reliability. The most common standardised shear strength test is the single lap shear test (ASTM D1002, ISO 4587). This test excels as a quality control (QC) check in detecting variation in the same adhesive and substrate combination, but changing stress distributions for different adhesive/substrate combinations make it problematic for comparing different materials, particularly those with different moduli (stiffness). Even more problematic (and this is true for any standardised strength test), it has limited ability to predict performance on geometries found in real-life assemblies. Testing on real-world assemblies under real-world conditions is essential to predict the performance of the bonded joint accurately.