4.4 Stresses on Joints

Adhesive performance is measured by its resistance to the forces acting on the bonded assembly. Laboratory results on standardised specimens, available in the adhesive manufacturer’s published technical data sheets (TDS), are an excellent tool for identifying candidate adhesives for an application. Adhesive candidates chosen based on these generic results should then be tested rigorously with simulated or actual end-use parts, assembly processes and operating conditions.

The physical forces acting on a joint may be classified as shear, tensile and compression loads, etc. They rarely occur purely as one type; in fact, some combinations are so common that they have their own names, such as peel or cleavage loading. Stress may occur at high speeds in the form of impact or as cyclic fatigue loads, and it may be static or dynamic. Thermal effects may impose stresses with differential expansion and contraction of a substrate or assembly. The more accurately these conditions can be simulated in testing, the better the prediction of the final assembly’s performance.

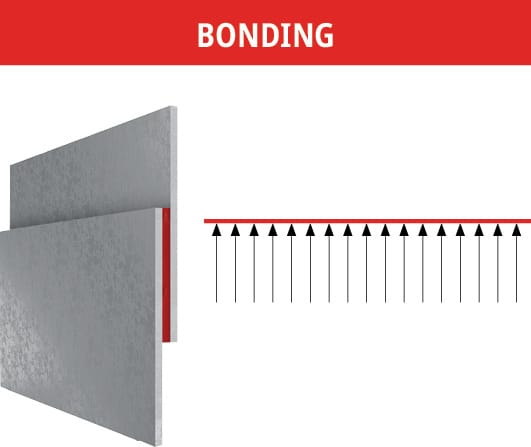

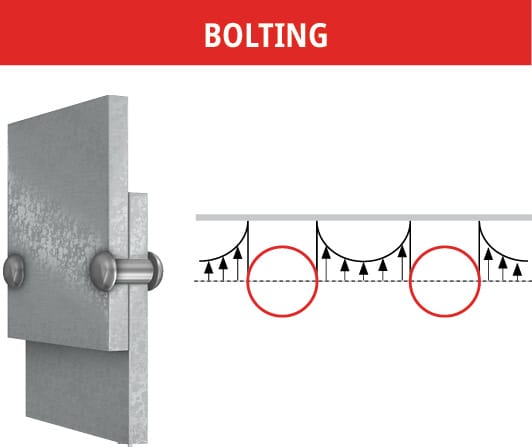

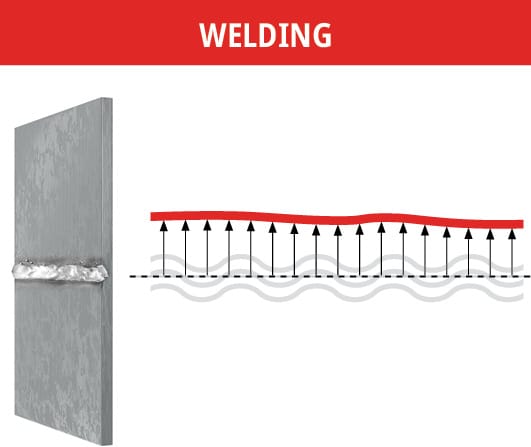

‘Force’ refers to the entire load acting on a joint or assembly. ‘Stress’ is force divided by the area supporting it; therefore, a small area results in higher stress. For mechanical fasteners and linear joints, such as welds, the force is concentrated in a relatively small area. Adhesive bonds can spread the force over a larger area, resulting in lower mean stress.

Mechanical and thermal joints manage stress differently from adhesives, as the following lists show:

Mechanical fasteners and thermal joining

- Create stress concentration points that may lead to substrate distortion or cracking

- Rely on bosses or holes that can weaken the structure and add machining costs

- Require reinforced connection points for concentrated stresses, increasing cost and weight

- Cause the applied load to be carried by a small area of the fastener

- Require tight tolerances

- Alter the substrate’s material properties with high temperature exposure (welding)

Adhesive bonds

- Distribute stresses and loads evenly across the bonded joint

- Eliminate the need for bosses and holes, limiting manufacturing stresses and fractures

- Compensate for more relaxed tolerances with gap-filling ability

- Seal, as well as join

- Can join a wide variety of geometries and materials