3.1.15 Electric Motors

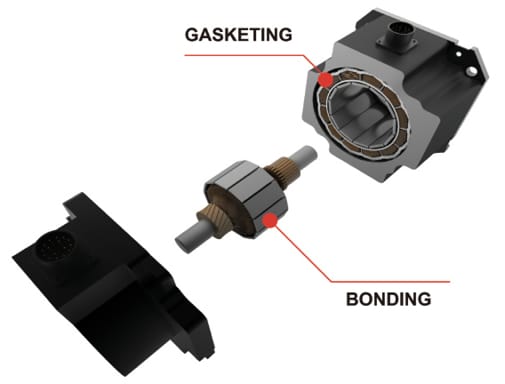

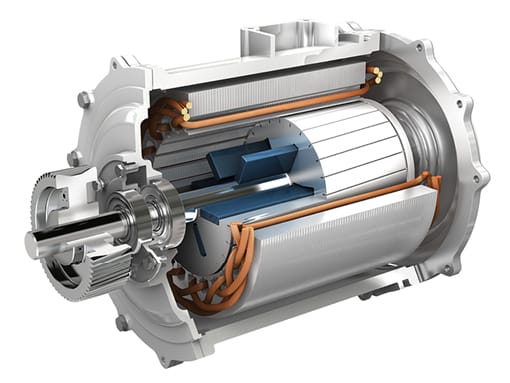

Millions of electric motors are manufactured worldwide every year. While the design and performance requirements of these motors vary, their manufacturers share many of the same challenges. As technology advances, the demand for smaller motors with greater performance increases, and motors must operate at higher temperatures and at faster rotational speeds. To remain competitive, motor manufacturers must eliminate waste and become as efficient as possible. To accomplish this, design and manufacturing teams must work closely together to improve their products and processes. Electric motors are more prevalent in automobiles than ever before, forcing motor designers to find new ways to maximise performance and efficiency while being as cost-effective as possible. Electric motor and generator manufacturers have used adhesives and sealants to improve performance, facilitate manufacturing processes and reduce costs for more than 60 years. Adhesives not only make improved manufacturing processes and speeds possible but also allow designers to select new or lightweight materials to enhance performance and improve reliability.

| E-MOTORS | Conventional/Traditional Method | Adhesive Solution |

Permanent Magnet

| Mechanical Fastening/Slots/Clips

| Magnet Bonding Solutions

|

Retaining

| Press Fit/Shrink Fit/Knurling on shaft

| Retaining Solutions

|

Preparing is caring

Check out LOCTITE® XPLORE's e-learning on surface preparation. It's free, fun and takes less than 10 mins.

Log in and select the chapter Introduction to Bonding and select Prepare to be Amazed to learn more.