1.1.7 Thermal Joint: Welding

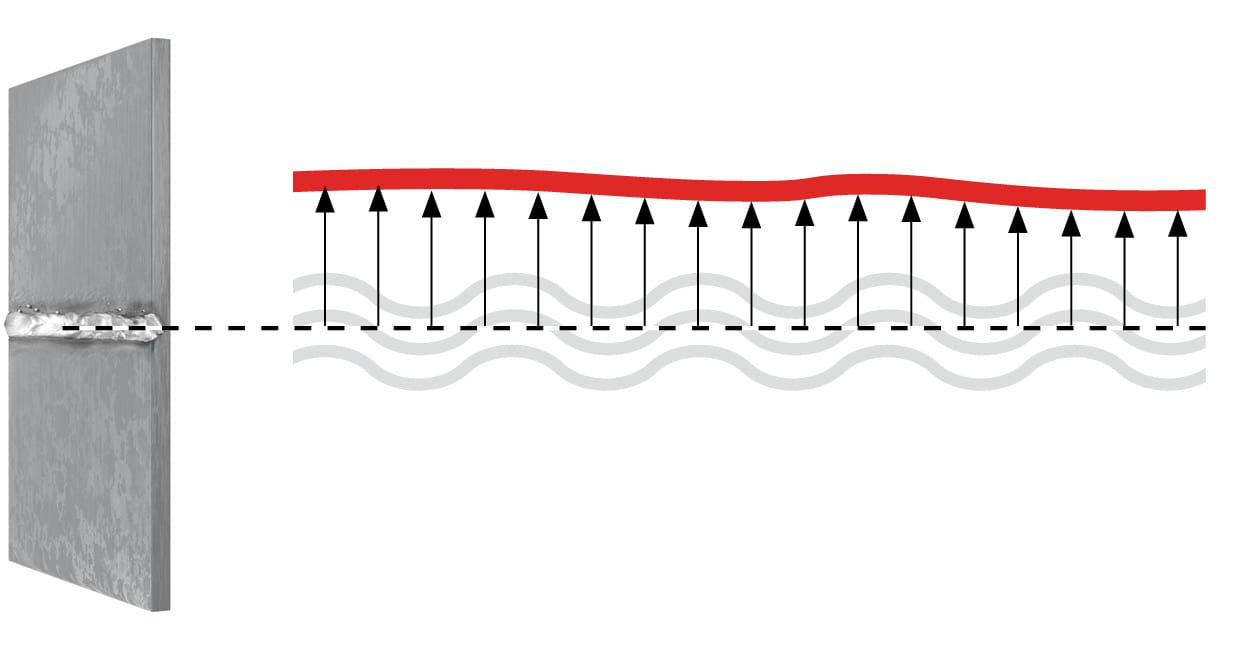

Welding is used to join similar metals. Welding produces a very strong joint and is generally suited to large assemblies where both metal sections are relatively thick (>= 12.7mm (0.5 in)). Welding creates a localised joint and is not suitable for broad areas. Welded joints are considered permanent as disassembly is impractical or impossible. Because the base material is melted, the part may undergo deformation, internal stresses and undesirable cosmetic effects. The ductility and toughness of the base material may be locally affected. Welding requires skilled labour and knowledge of basic physics, chemistry and metallurgy principles. Highly flammable gases and/or specialised equipment are also required. Welding is not suitable for small items.

1.1.8 Thermal Joint: Soldering

Soldering joins metal parts with a molten filler metal rather than melting the base material of the part. Solder is typically a tin or lead alloy that melts at temperatures below 350°C (662°F), causing less thermal stress than welding. Melted solder is drawn by capillary action between metal surfaces. It is electrically conductive, suitable for small parts and may be reworked at relatively low temperatures, which makes it a popular choice for electronics.