1.1.5 Mechanical Joint: Press Fit

Press fits, or interference fits, involve an inner component, such as a shaft, forced into an undersized hole. Once assembled, the parts are held together by the friction of the press fit. Press fits require machining to tight tolerances and precise, accurate placement at high force, typically with a hydraulic press.

1.1.6 Mechanical Joint: Shrink Fit

A shrink-fit joint is an extreme form of an interference fit. The negative clearance is larger than that of a standard press fit, with the outer diameter of the inner element being significantly larger than the inner diameter of the component or sleeve into which it is pressed. To achieve this assembly, the outer sleeve is heated before the inner component is forced into it. Because the outer element will cool very rapidly and the inner element will heat up, the assembly must be completed quickly as it will not be adjustable once it has cooled. In addition, the outer component will be under high stress and may be designed to be larger and heavier to compensate.

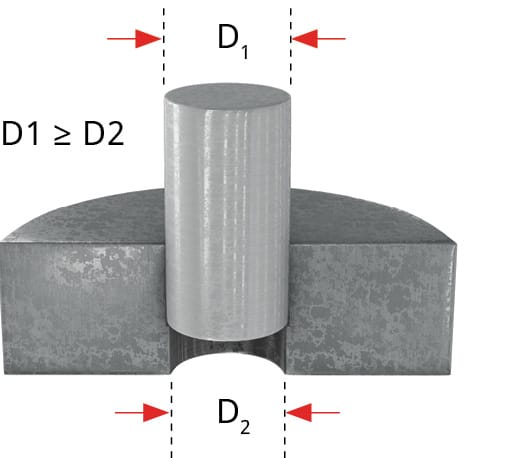

Press-fit joints and shrink-fit joints can cause high stresses that lead to the destruction of the assembly (Figure 12), especially during the operating time when the hub has a load caused by a torsional moment.