1.1.2 Mechanical Joint: Rivets

Rivets are cylindrical shanks with a head at one end used to permanently join two plates. Like threaded fasteners, they require holes to be drilled into the materials being assembled. After insertion through the holes, the end of the rivet shaft opposite the head is flattened and deformed so that it cannot be removed, securing the parts together. Because it cannot be disassembled without destroying the rivet, it is considered a permanent joint. Like threaded fasteners, rivets may cause stress concentrations that require components to be reinforced at these locations, adding to the weight and machining requirements. Also, like threaded fasteners, rivets do not seal leak paths and are vulnerable to corrosion.

Figure 6 A mechanically joined assembly; lack of sealing capability leaves assemblies vulnerable to moisture ingress and subsequently corrosion

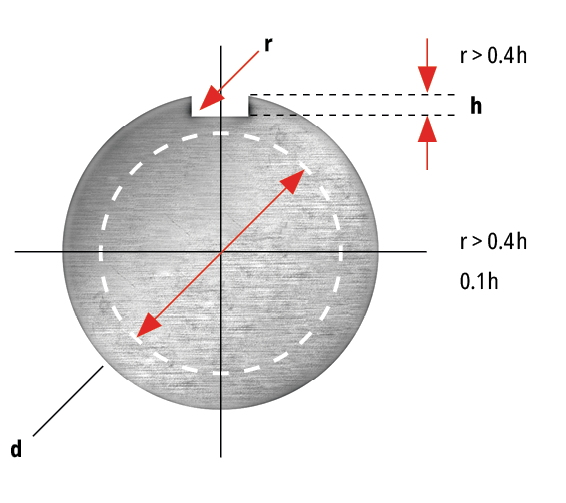

1.1.3 Mechanical Joint: Keyway

Keyways transmit torque between a shaft and gear by means of a rectangular key secured to the shaft by dowels, pins or set screws. Machining costs for tolerances required by keyways may be significant. The diameter of a shaft in which a key is seated must be increased by up to 30% to accommodate the key while supporting the torque load.