1.1.1 Mechanical Joint: Threaded Fasteners

Threaded fasteners are the ideal method of mechanically joining elements when occasional and easy disassembly of the joined parts is required. Threaded fasteners require the expense of drilling and tapping the parts to be joined, often to specified tolerances. The fastener sites concentrate stress, which, if severe enough, may require the parts to be reinforced at those points. Threaded fasteners can provide a very strong clamping force but may fail over time due to vibration and cyclic loading, and corrosion is a concern in humid, marine or chemical environments. Adding a chemical bonding agent – an adhesive – to a threaded fastener can reduce or eliminate many of these issues. For an in-depth discussion of threadlocker adhesives and threaded assemblies in general, refer to the manual in this series titled How to Increase Reliability and Prevent Threaded Assembly Failure.

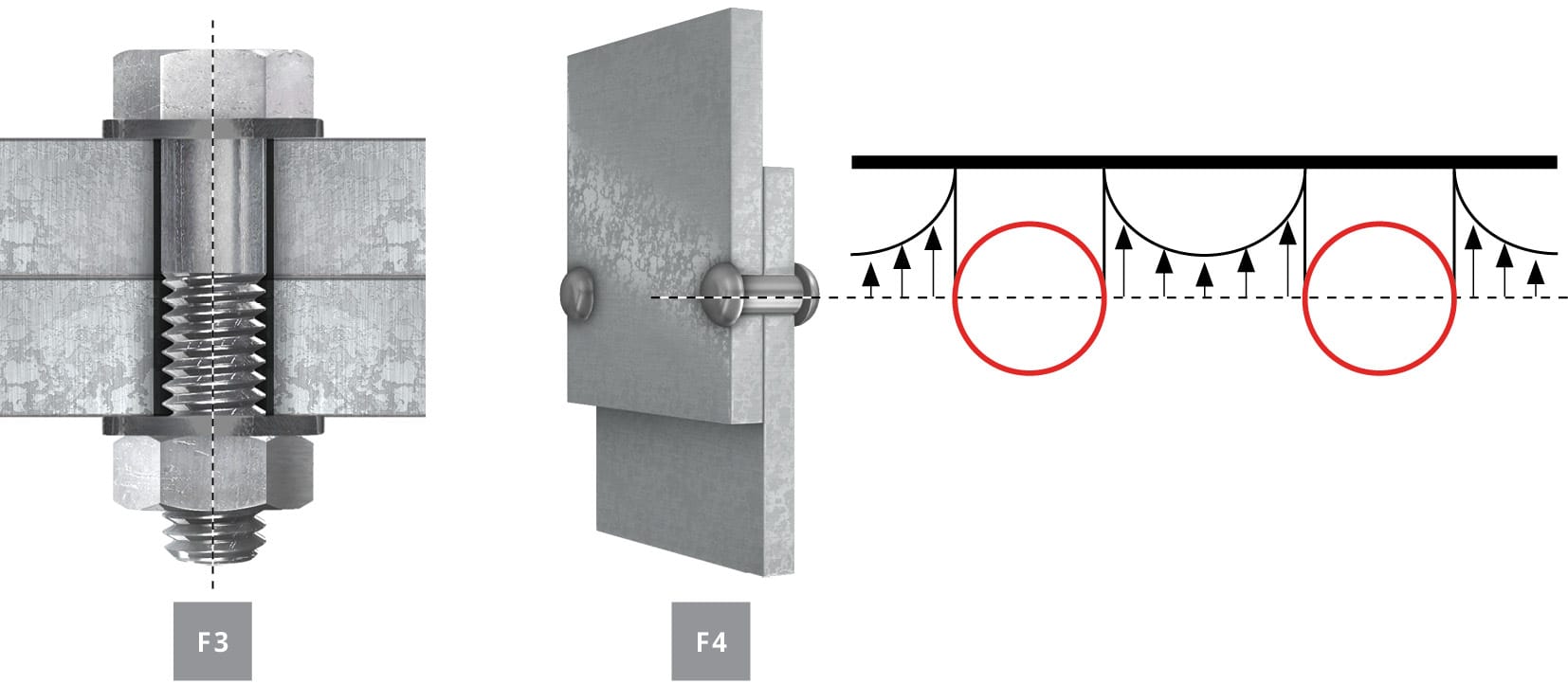

Figure 4 Stress risers occur at threaded fastener or rivet locations